OUR EXPERIENCE

AT THE SERVICE

OF YOUR PROJECTS

OUR CERAMICS ACTIVITY

For decades, the CLEIA teams, formerly CERIC TECHNOLOGIE, have passionately participated in all the major innovations of the profession which are the reason for terra cotta construction materials being famous today.

We control all the manufacturing, drying and firing processes with excellence (which are essential to the design of turnkey plants) in any region in the world.

Beyond the process performances, our hybrid or zero emission avant-garde designs guarantee even more effective terra cotta products.

mission

FROM THE QUARRY TO THE OPERATION

SOLUTIONS ADAPTED TO YOUR NEEDS

RELIABLE EQUIPMENT TO OPTIMISE YOUR PROFITABILITY

CUSTOMISED ENGINEERING

TYPES OF PROJECTS

Green field brickworks and tile works

Production line renovation and modernisation

Innovation for the benefit of the operation

WHAT WE OFFER

YOUR PRODUCTS

VSI BRICKS

HOLLOW BRICKS

FACING BRICKS

HOURDIS

SLIPS

ROOF TILES

FITTING

PAVERS

CERAMIC CLADDING PLATE

TECHNICAL CERAMICS

CERAMICS

SOLUTIONS

GROUND PREPARATION

The first step of the ceramic process concerns the preparation of clay. The raw materials extracted from their quarry are measured, grinded, then mixed in order to form a clay paste fit for the shaping of the products.

SHAPING

We incorporate shaping equipment such as moulders and their dies, as well as presses, regardless of the types of moulds used (plaster, steel or rubber sheet). This allows us to shape all product types (solid or ventilating bricks, Spanish, flat or interlocking clay tiles, or even paving tiles).

STORAGE

The storage of raw materials is a key step in the preparation of the mixture. We incorporate the best solutions of the market in order to guarantee the availability, composition and homogeneity of the required mixture.

DRYING

The drying of ceramic products is a delicate stage of the production. CELIA has great experience and is an expert in the drying technologies to be implemented according to the products to be manufactured and the raw materials available. Thanks to continuous innovation and many patents, our dryers are the most effective ones in the market.

Zéphyr®: Scalable and innovative

Sirocco: Fast and robust

DT Energy: Smart and environmentally friendly

Tunnel MV: Large capacity and multi-product

FIRING

We have developed a wide range of kilns (tunnel or batch type) and wagons made of refractory parts for temperature ranges varying from 900 to 1300°C. We offer effective firing equipment with consumption reduction systems for all energy types: gas, biomass, hydrogen, electrical etc.

Tradifast: Robust design – brick and suspended roof

Ecofast: Economic solution – casing

Technofast: The most technical – 100% refractory parts

Wagons: Design for bricks and tiles

HANDLING

Our interprocess circuits are designed

according to the products to be handled

at each production stage. Traditional or

automated production cells such as Loaders/Stackers/Unstackers/

Palletisers/Storage Operators.

They are on a line or served by a fleet of mobile robots such as AGVs/AMRs/Shuttles, with or without intermediate storage, in order to guarantee a flexibility of the flows adapted to the process requirements.

Types of handling circuits:

Cutters: Standard cutting lines and multi-wire cutter

Loaders: All types of dryers and products

Stackers/Destackers: Traditional or with robots

Packaging: Customised packaging line

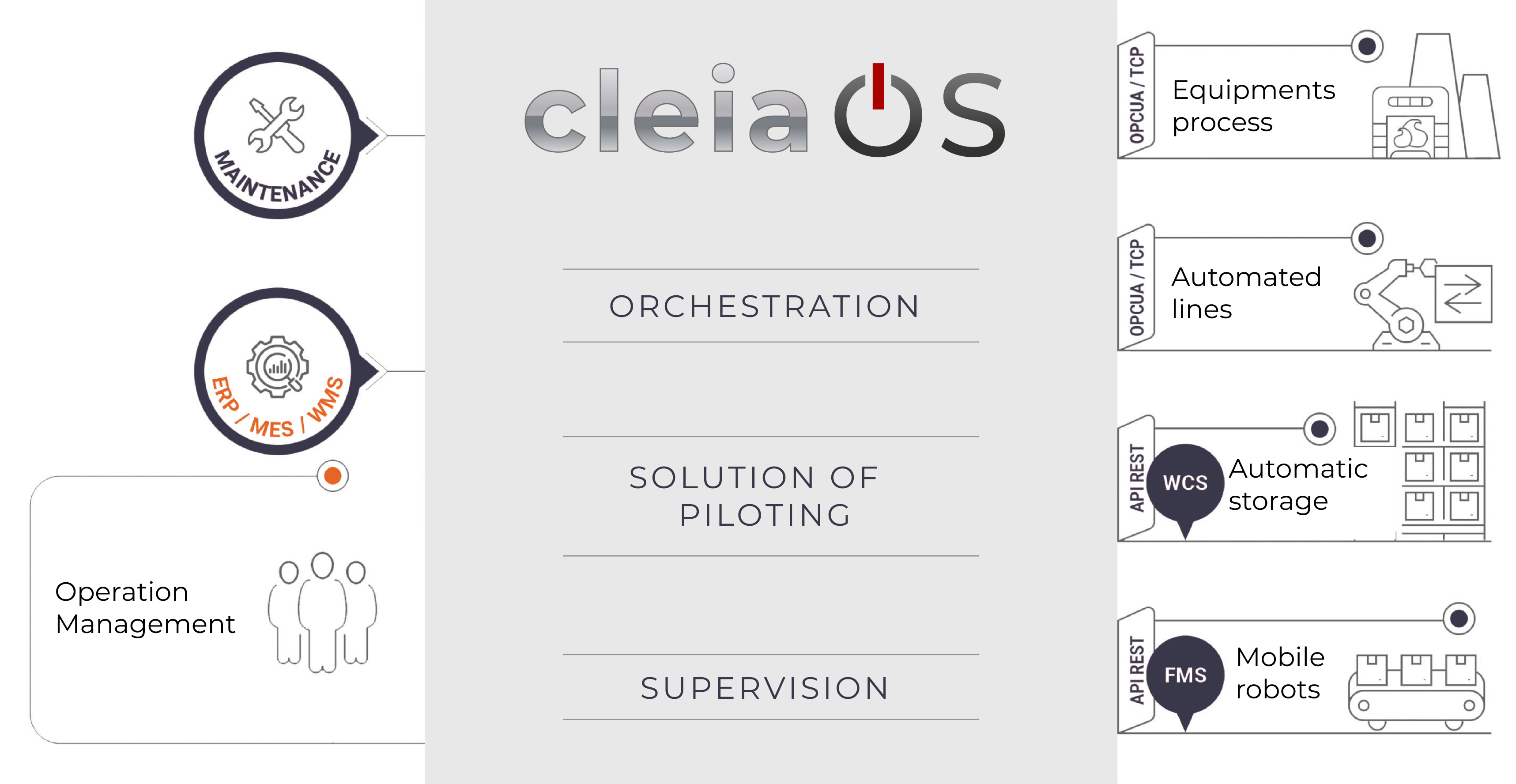

CLEIAOS, THE ORCHESTRATOR OF YOUR PRODUCTION

The advantages of cleiaOS

cleiaOS offers key intuitive orchestration, optimised maintenance and global supervision functionalities, all with a no-code approach, thus facilitating the deployment and adaptation of the system.

With cleiaOS, our industrial IT solutions offer complete visibility of the operations, enabling better planning, real time monitoring and effective decision-making.

This allows for connected, reactive and quality-orientated plant management.

PARTNERS

BRANCHES

Since our beginnings in the 1960s in Nolay under the name of CMH and since going from our strategic alliance with the Ceric group under the name of Ceric Automation to our resurgence as CLEIA, our history is rich and we have a global influence.

CLEIA’s Ceramics department is much more than just a section of our company. It is the heart of our passion, our expertise and our commitment towards our clients. We are proud of each tile and brick produced thanks to our solutions, and we are anxious to continue breaking new ground for the future of the terra cotta industry.

AND AFTERWARDS?

Our ability to provide you with a complete after-sales service which covers many technical skills and has great reactivity, is one of CLEIA’s biggest strengths.